Integrity

With over 50 years of casting excellence, Yuan Run Feng (YJF) is expanding into the international high-end machine tool market through professional custom product combinations and upstream-downstream integration. YJF exports primarily to Europe, the United States, and Japan, ranking first in export value across Taiwan.

Driven by a commitment to quality and customer satisfaction, YJF introduced advanced precision machining equipment in 2023, integrating diverse manufacturing processes within a smartly controlled facility. This established an advanced manufacturing hub for key components in Asia, providing comprehensive end-to-end (E2E) services to achieve smart manufacturing and sustainable operations.

Integrity

Industry Components

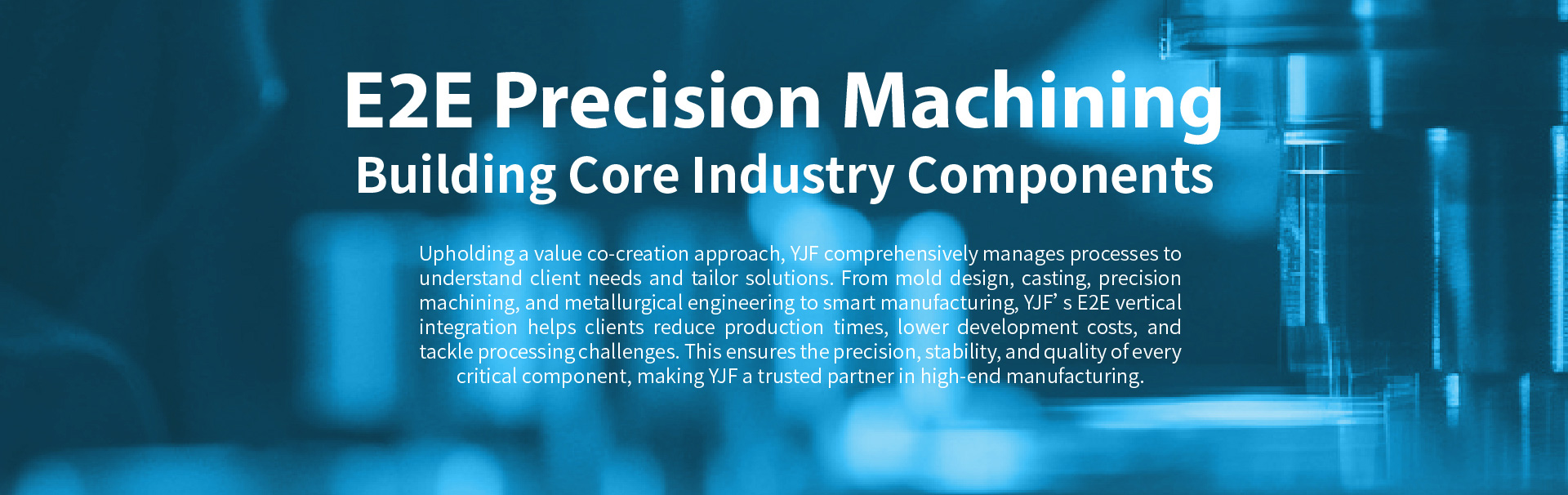

Upholding a value co-creation approach, YJF comprehensively manages processes to understand client needs and tailor solutions. From mold design, casting, precision machining, and metallurgical engineering to smart manufacturing, YJF’s E2E vertical integration helps clients reduce production times, lower development costs, and tackle processing challenges. This ensures the precision, stability, and quality of every critical component, making YJF a trusted partner in high-end manufacturing.

×

Technical

Highlights

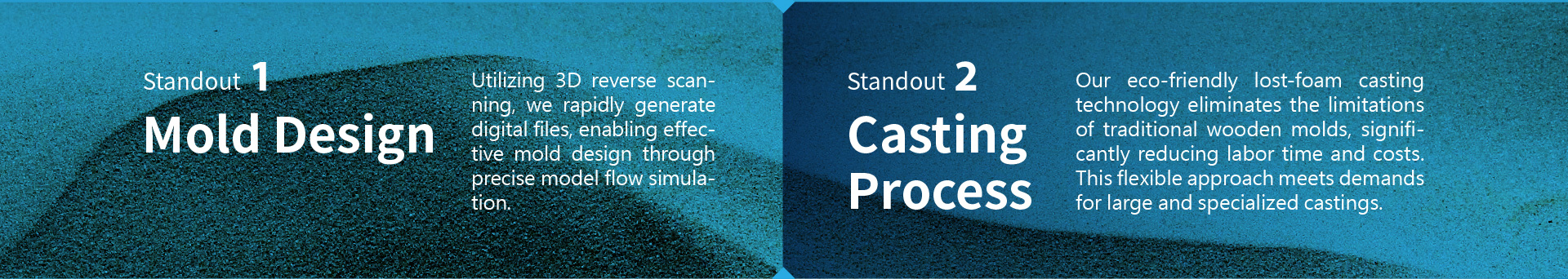

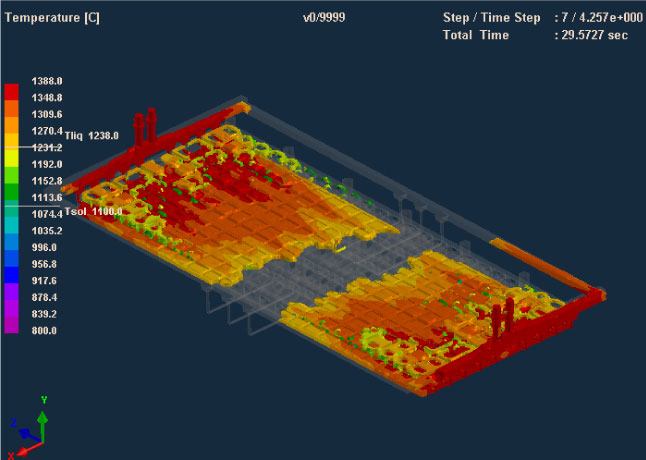

Utilizing 3D reverse scanning, we rapidly generate digital files, enabling effective mold design through precise model flow simulation.

Our eco-friendly lost-foam casting technology eliminates the limitations of traditional wooden molds, significantly reducing labor time and costs. This flexible approach meets demands for large and specialized castings.

Emphasizing accuracy in μm level accuracy and tolerances, YJF’s smart control systems optimize production to balance high precision with efficient output.

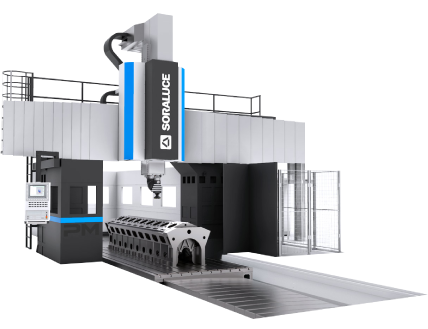

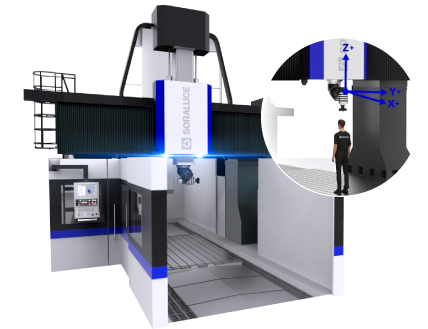

Designed for high-precision cutting of large components, with maximum travel dimensions of 5600mm(length) ×4000mm(width) ×2000mm(height), ensuring tolerance control for heavy workpieces in machinery and energy sectors.

Machining Center

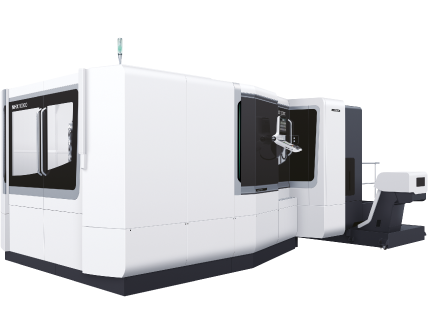

Accommodates workpieces up to Ø2000mm × 1600mm. With multi-pallet systems, complex parts undergo multi-surface machining in one setup, shortening workflows and enhancing precision.

Covering surface and heat treatments to improve component durability and stability. SIP inspections and gauge measurements ensure precision and performance, catering to the aerospace, energy, and machinery industries’ rigorous standards.

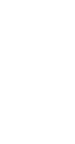

Adopting the APQP (Advanced Product Quality Planning) system for process management, YJF meticulously plans all critical steps to meet inspection standards, identifying potential risks early on with preventive actions. SIP inspections at each phase establish operational consistency, and gauge inspections ensure dimensional and tolerance accuracy. This thorough QC process assures each component meets client expectations for performance and quality.

Integrating unmanned transport systems and smart production management, YJF optimizes processes to reduce carbon emissions, achieve efficient and green manufacturing, and minimize labor reliance. This accelerates production cycles, enabling rapid mass production and enhancing market responsiveness.

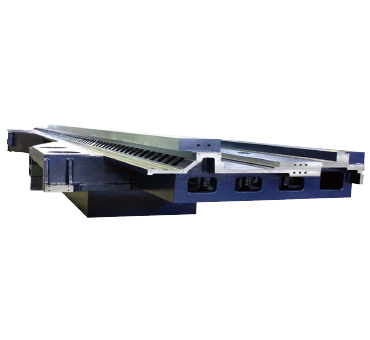

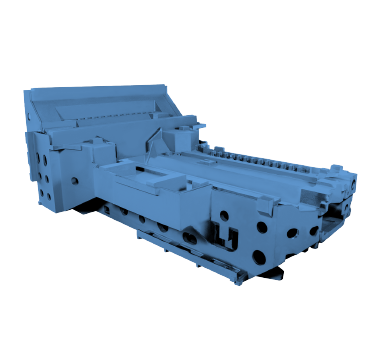

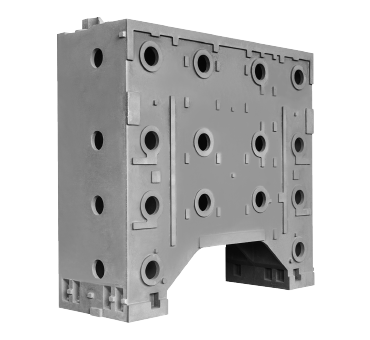

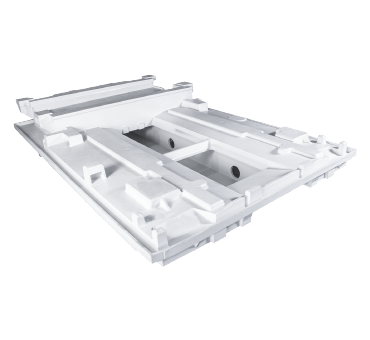

Crossbeam

Table

Double Column Machine

Column

Horizontal Boring Machine

Base

Horizontal Machine Center

Column

Horizontal Machine Center

Column

Gear Hobbing Machine

Base

5-axis Machine Center

Table

Vertical Lathe

Applications