Please Select

01Design Phase

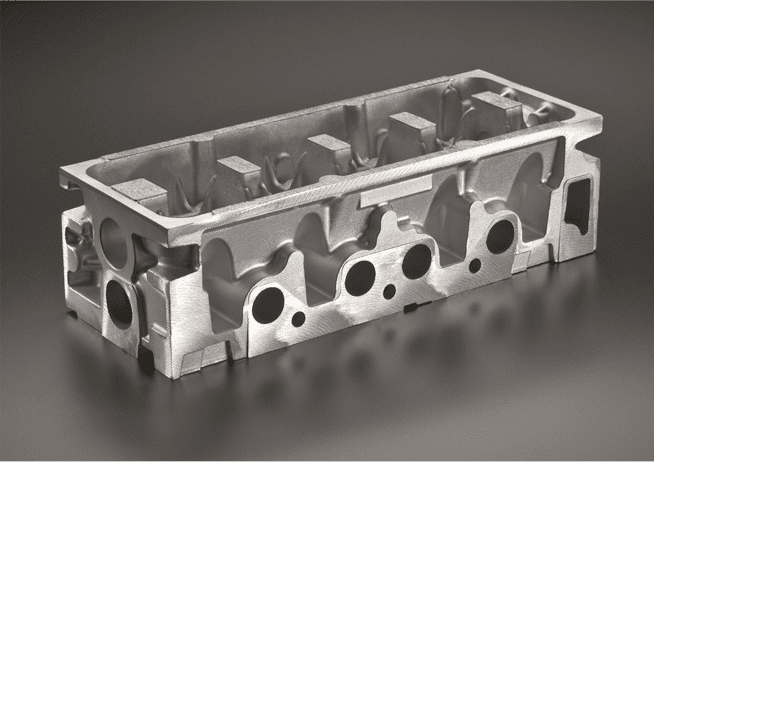

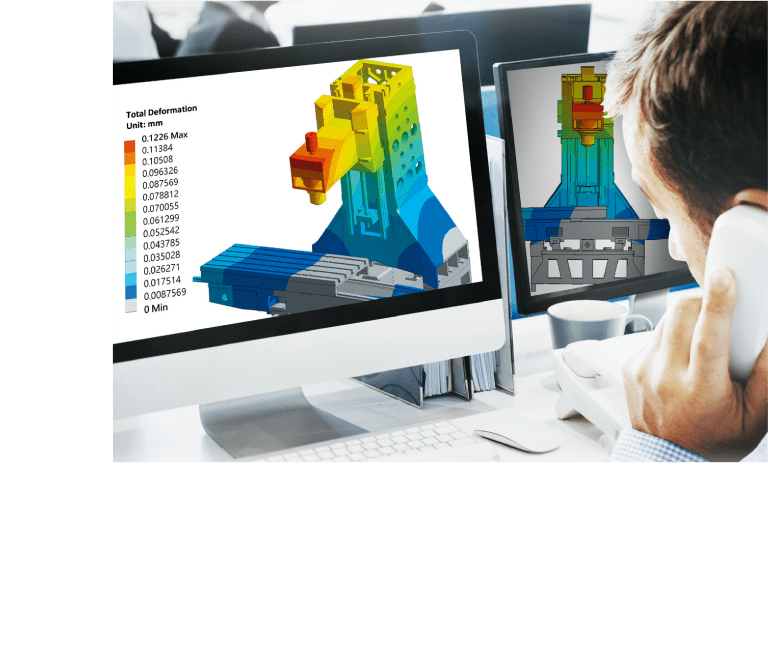

YJF gets hold of quality right from the beginning. Every batch of raw material must pass incoming inspection. Along with the production, we identify all key parameters and apply CAE simulation for casting formation and solidification.

By combining strong design capabilities and proprietary processes, we deliver precise, optimized machining allowances to maintain strict dimensional accuracy—ensuring the first casting and the thousand that follow are equally consistent.

The latest lost- foam casting is provided to offer high flexibility in casting extra large and special-spec product. Not only it massively shortens lead time, but also reduces wooden pattern usage, and therefore lowers total development cost.

Throughout design optimization, YJF solutions effectively reduce stress concentration, casting defects and deformation caused by solidification and cooling, ensuring stable performance of the finished casting.

02Casting Phase

We are capable to produce single-piece grey iron castings up to 50 tons and ductile iron castings up to 30 tons. Within in the next 2 years, 70-ton of grey and 45-ton of ductile will be available.

With advanced melting technology, we ensure that our product maintain accuracy even under heavy-duty loading conditions.

Additionally, our plant is equipped with two stress-relieving furnaces, sized 16 m × 4 m × 4 m and 10 m × 4 m × 4 m. By using production data and process records, we precisely control heating temp to achieve effective stress relieving, minimizing structural deformation.

03Machining Technology

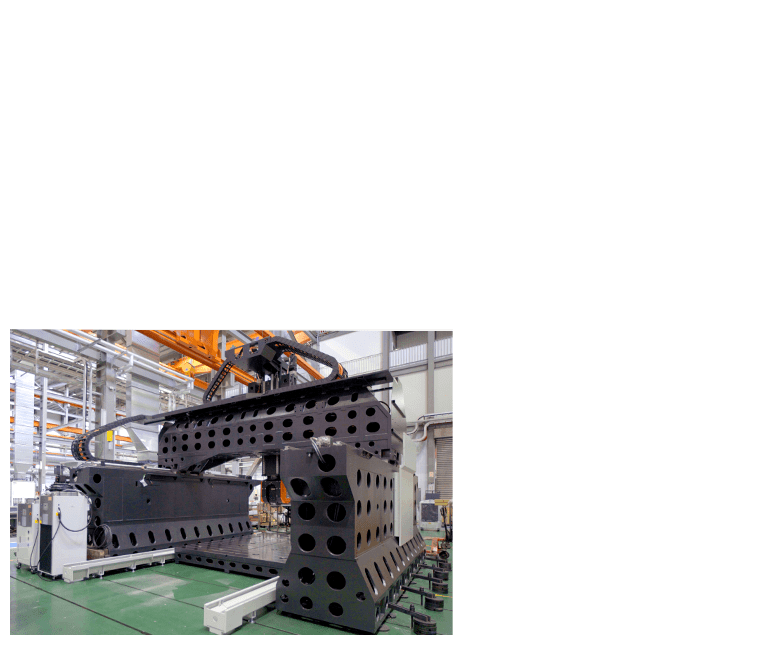

Our machining processes include milling, drilling, heat treatment and grinding for large iron castings.

Some of our machining equipments are large gantry milling machines from EU and five-axis mill-turn machining centers from Japan. With micrometer-level machining accuracy, these machines enable customized machining solutions for highly durable and high-precision components, meeting the demanding standards of the aerospace, machine tool and industrial machinery sectors.

04Quality Assurance and CMM Reporting

AKey QA equipment in our foundry includes spectrometers, metallographic analysis systems, ultrasonic testing equipment, and full-process inspection for resin, sand and hardeners. In addition, the tensile testing machines are used to verify the tensile strength of castings, while impact testing machines provide low-temp impact test data at -20°C and -40°C for critical components.

Before shipment, we provide complete CMM (Coordinate Measuring Machine) reports to verify the dimensional accuracy of every casting product.

05After-Sales Service

After-sales service is the backbone of our castings in the field. To YJF, the connection with each customer and each casting just begins after the product ships to our customer. By offering complete production records and process data analysis, we get hold of all manufacturing and QA information throughout the entire process.

We provide full digital traceability for every casting. QR codes are used to record and link process info, enabling fast tracking and verification whenever customers requires.

06International Certifications

As a Meehanite licensed foundry and an ISO 9001-certified manufacturer, we want to be a sustainable corporate, and our ISO 14001, ISO 14064-1 and ISO 14067 are ready here to pin the starting point of our ESG roadmap.